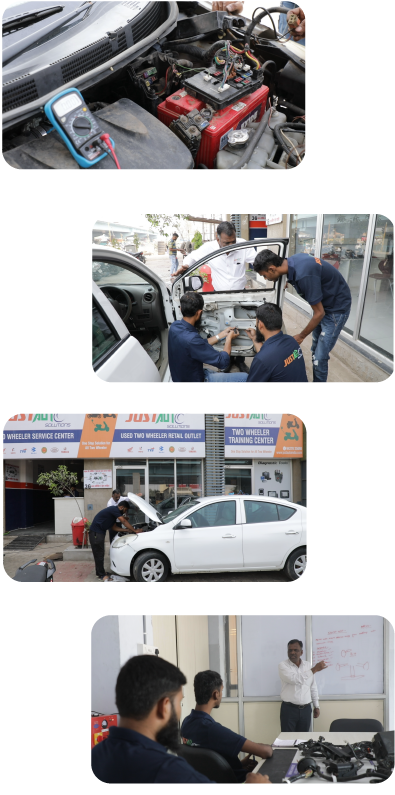

The training begins with safety aspect in general and specific to the trade, identification of

tools & equipment, raw materials used. The trainee will perform precision measurements on

the components and compare parameters with specifications used in automotive workshop.

He learns to carry out basic fitting operations used in the workshop practices and inspection of

dimensions. The trainee performs grinding of testing tools and surface finishing operations in

the given job.

He also understands the constructional features and working principles of MPFI system and different types of sensors in

engine. The trainee identifies EDC components, sensors, actuators, major components of car

AC, automotive lighting system and carries out repair & maintenance.

Car Wiring

Content of Course

We will help you to learn:

- Starter / Alternator - Stop Start systems and alternator management systems including the battery monitoring sensor

- Hybrid Alternator

- Fuse - Protection of circuit from overload

- Relay - ISO and DIN standard relays; Relay controlled circuits; Testing relays

- Pulse / maintenance type battery chargers

- Wiring system - wiring diagram; circuit testing routines

- Oscilloscope- Diagnostics menus and settings; Testing electrical systems and components

- Horn, Headlight and other lights

- Sensors - Testing sensors and actuators in petrol and diesel engine management systems

- Testing of spark ignition systems and petrol and diesel common rail injector control circuits